Mother Nature is Silent Design Partner at Richardson International

Although environmentally conscious building practices are not the norm in the airport industry, they're a top priority at Winnipeg James Armstrong Richardson International Airport. In a province that runs entirely on clean hydroelectric power, a "green" terminal was the natural choice for sending passengers off into the wild blue yonder.

"In Manitoba, environmental responsibility is just part of our psyche," explains Winnipeg Airports Authority president and CEO Barry Rempel.

After a full year of construction, Rempel is optimistic about costs for the $200 million terminal scheduled to be complete in December 2009.

|

|

"When we were setting our agenda back in 2002, I was concerned that 'going green' would drastically increase our expenses," he recalls. "We're finding that if you build properly, what's good for the environment is also good for business."

Environmental Economics

Balancing effective design, cost-efficiency and environmental stewardship was a constant focus for Stantec Architecture. "Progressive, yet pragmatic" is how senior vice president Stanis Smith describes the design approach the firm used to strike the right balance.

"We're leading edge, but not bleeding edge," Rempel stresses. "We're using technologies that are proven to work, rather than striving to be first." Declining prices of building materials - especially "green" ones - and a number of environmental building grants and energy efficiency incentives are helping tip the economic scales in the airport's favor.

Stantec officials estimate "going green" accounts for about 2% of the total budget. Because Winnipeg is the first Canadian terminal to formally register for third-party certification through LEED (Leadership in Energy and Environmental Design), the Province of Manitoba provided $75,000 for such fees. Other costs include ongoing environmental audits, additional expenses for Earth-friendly materials and a series of brainstorming charettes to elicit input from airport employees, environmental specialists and members of the public at large.

The extra costs, however, promise lower energy consumption and reduced operating expenses.

"In the end, we'll provide a larger facility capable of meeting stakeholder needs without increasing energy costs," enthuses Rempel. "It will operate extremely efficiently."

Even before it's complete, the terminal is already setting a striking example of environmentally conscious building design in Manitoba and the airport industry worldwide. Based on figures provided by EcoSecurities, a private firm that measures and works to reduce carbon emissions, Stantech estimates Winnipeg's new terminal will save approximately 2,000 tons of greenhouse gases per year. In a province powered by coal, the improvement would be exponentially greater.

"It's an exciting opportunity to take an abstract concept like 'sustainable design' and make it concrete," says Smith. "Winnipeg is taking a visionary approach. If other airports don't act in a similarly responsible manner, their ability to expand and grow to meet demand will be constrained."

Savings Are in the Air

The displacement ventilation system specified for the new Winnipeg terminal accounts for the most significant portion of its energy and cost savings.

"In conventional buildings, the air supply is blown in from above," explains Smith. "By moving the supply points closer to the floor and adding radiant floor heating and cooling, we drastically reduce the volume of air we heat or cool to keep occupants comfortable. We only treat the space that people occupy rather than the entire volume."

With 45-foot ceilings in the 30,000-square-foot passenger atrium, the energy and cost savings add up quickly.

The strategy for lighting is similar to ventilation. "We brought lighting sources closer to where the people are, making them more energy-efficient and people-friendly," Smith explains.

Engineers also developed special systems to capture excess heat generated by computers and electrical equipment. With a negligible amount of energy, it is reused to heat or cool passenger areas. A series of cascades, for instance, extracts heat from boiler exhaust, yielding a system efficiency of more than 90%. Overall, the terminal is expected to be 44% more energy efficient than Canada's Model National Energy Code for Buildings.

Although the Airports Authority did not mandate a specific period for environmental elements to "break even," many will provide almost immediate operating savings. "The payback point of environmental materials used to be 10 to 15 years," recalls Smith. "These days, it's accelerated to three to five years."

Not Just Green

While environmental responsibility was a key goal, it was not allowed to eclipse fundamental design objectives. Everything came back to the "passenger experience."

"It's not enough to create a pleasant or comfortable space," explains Smith. "We wanted to delight passengers. The airport is an ambassador for Winnipeg - it's the first thing residents and visitors see when they arrive and the last thing they see before leaving. We want it to be a point of pride for the entire city and province."

Ample natural lighting in the open-air passenger atrium, for instance, saves energy, but it also evokes a pleasant feel. "It's not all about cost savings," qualifies Smith. "It's about creating a memorable passenger experience."

Architects maximized the amount of natural light in the atrium with clerestory windows and skylights throughout the 30,000-square-foot area. They also, however, minimized glare for employees working at computer terminals by cantilevering the roof almost 46 feet.

With only about 15% of travelers expected to check in at the new terminal, square footage needed for that area was actually reduced. Research shows the vast majority of passengers will check in from home computers or via portable web devices en route to the airport.

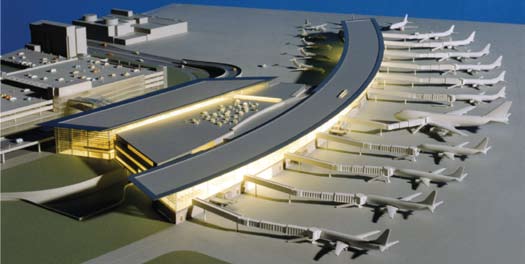

Designing an entirely new building provided architects with the unique opportunity to completely re-think passenger flow within the terminal. Transparency - achieved through careful planning and the liberal use of glass "walls" - will allow passengers to see their aircraft at the gate from the check-in area and help them navigate easily and intuitively.

Common use check-in counters and baggage handling systems were specified to improve efficiency and flexibility for carriers and enhance service for passengers. Travelers won't line up by carrier; any kiosk will work.

Even the terminal's unique functional features, however, are likely to be overshadowed by its environmental elements. As the first airport in North America to register for LEED certification, it's sure to be watched for years.

"We take our role very seriously," says Rempel. "It's not often you get a chance to impact a business and community in such a major way. We're intent on getting it right."![]()

FREE Whitepaper

Fairbanks International Airport Baggage Transport Conveyor Enhanced With Mod Drive™ System

Airports face a host of unique industry challenges, such as meeting efficiency regulations and seeking out the best maintenance practices to reduce costs and keep operations flowing. In today’s current economic climate, any potential cost savings can go a long way.

In 2019, Alaska’s Fairbanks International Airport (FAI) sought to modernize its equipment and operations. They were dissatisfied with the performance of the gearmotors on their baggage transport conveyors and began searching for new suppliers. Regal approached FAI with a solution that could improve equipment performance and simplify maintenance, with the added benefit of energy cost savings: the Hub City® MOD Drive™ system.

This white paper discusses the hardware deployed, the test results and the annualized expectations for ROI.

Comment:

I lived in Winnipeg for 30 yrs. and feel it's about time they got a little more modern with their terminal. I have traveled a lot and I feel they could use a few more restaurants on the airside of the terminal.

Posted by: Ian MacArthur