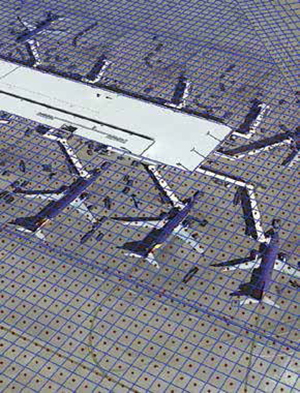

Dallas Love Field Prepares for the Future with Timely Pavement Management Program

In early 2014, the city of Dallas and Dallas Love Field (DAL) were in a unique and ultimately timely position from operational and funding perspectives alike. The expiration of the Wright Amendment in October 2014 allowed air carriers to modify flight routes out of DAL, thereby increasing air traffic and changing the aircraft types needed to handle traffic. In addition, the upcoming 2017 expiration of the letter of intent associated with the long-running Love Field Modernization Program will make federal discretionary and entitlement dollars available for airfield-related projects that had been deferred because of the modernization program.

With these upcoming changes, city officials agreed that DAL was due to update its pavement management program. (The last time that occurred was in 2008.) In April 2014, six months before the Wright Amendment expired, Kimley-Horn and Associates initiated a thorough evaluation of DAL's airfield pavements to provide background data for a reasonable maintenance and rehabilitation schedule. The firm was also tasked with developing a 10-year capital improvement program that the city of Dallas could trust for budgeting project costs and was phased to minimize impact on airport operations.

Jennifer Nicewander, senior engineer for the city's Public Works Department, reflects on the timeliness of the project elements: "The year we were scheduled to do a pavement evaluation was the year before the terminal would open with its additional gates and the Wright Amendment would expire. We were able to learn the condition of our pavements right before we would have a huge increase in air traffic."

FACTS&FIGURES FACTS&FIGURESProject: Comprehensive Airfield Pavement Management Program Location: Dallas Love Field Timeline: April 2014-Dec 2014; additional reevaluation & report in March 2016 Cost: $1.2 million Funding: Airport Improvement Program (75%), Dept. of Aviation (25%) Project Manager & Technical Elements: Kimley-Horn & Assoc. Records Research & Pavement Condition Surveys: Parsons Brinckerhoff Records Research, Pavement Condition Surveys, GIS Integration: IBARRA Consulting Engineers Nondestructive Pavement Testing & Geotechnical Investigations: HVJ Assoc. Structural Pavement Evaluations: Pavement Technical Solutions Quality Control: Roy D. McQueen Engineering Consultants Automated Pavement Management System: PAVER(tm) Of Note: Timely pavement management program arms airport with capital improvement program to handle future airfield projects resulting from 2014 expiration of Wright Amendment & associated air traffic increases |

The pavement evaluation confirmed that quite a bit of work was needed, she adds.

DAL was in a unique position, explains Kimley-Horn Project Manager Craig West. Airfield projects suffered because discretionary funding was tied up with the terminal Modernization Program. With the upcoming increase in traffic and heavier aircraft, pavements would be impacted.

"Our goal was to position Love Field with a bulletproof CIP (capital improvement program)-a plan that the FAA could value and trust and would position the city and airport to receive funding for large-scale airfield improvement projects once the letter of intent expired," West elaborates.

Multi-Pronged Strategy

The airport took a comprehensive approach to updating its pavement management program, including visual, structural and detailed geotechnical evaluations. The scope of work included:

• reviewing as-built records from 1955 to the present for all areas of the airport;

• updating the existing 2008 pavement network definition plan, identifying branches, sections and sample unit locations to reflect current conditions;

• visual inspection of airside pavements;

• nondestructive testing and structural evaluation of airside pavements with a falling weight deflectometer;

• geotechnical investigation of entire airfield;

• updating existing PAVER(tm) database and customization information, including maintenance strategies, prioritization guidelines and unit cost data;

• economic analysis using constrained and unconstrained budget scenarios to develop a recommended maintenance and rehabilitation program for a 10-year capital improvement program;

• structural pavement evaluation to determine remaining life, pavement classification numbers and rehabilitation alternatives; and

• integration of functional and structural condition data into a realistic, prioritized capital improvement program that considered DAL's specific construction phasing and operational constraints.

Kimley-Horn performed a two-phase visual condition survey in May and July 2014 in concert with planned runway closures. During the surveys, crews inspected nearly 15 million square feet of airfield pavement, including runways, taxiways, aprons, shoulders and blast pads. Visual condition data collected during the pavement condition index (PCI) inspections were entered into the PAVER(tm) database, which in turn calculated the current PCI for each sample unit and section.

Using data based on the airport's historical PCI figures, the report predicted future PCI values and pavement condition in five years (2019) and 10 years (2024) if DAL would choose not to perform any major airfield pavement rehabilitation.

HJV Associates conducted a geotechnical investigation to determine pavement composition and subgrade conditions. The company also provided a detailed review of existing geotechnical data and construction history data contained in the 2008 pavement management program. Crews retrieved 114 pavement cores and drilled 16 geotechnical borings.

Under the supervision of Pavement Technical Solutions, HJV performed nondestructive deflection testing during May and July 2014 on all airfield pavement sections to determine potential areas of structural deficiencies.

Under the supervision of Pavement Technical Solutions, HJV performed nondestructive deflection testing during May and July 2014 on all airfield pavement sections to determine potential areas of structural deficiencies.

Variations notwithstanding, Kimley-Horn found that the majority of DAL's pavement sections had structural remaining lives greater than 10 years. Furthermore, the structural analysis results largely aligned with the functional analysis results-that is, most sections exhibiting poor functional remaining life also showed poor structural remaining life values. The report recommended these sections be targeted for reconstruction in the capital improvement program.

Some pavement sections, however, were found to be performing well functionally in spite of poor theoretical structural remaining life values. Taking into consideration the unique nature of many pavement sections at DAL, the team recommended that these sections be monitored closely for further deterioration and crews address signs of structural distress as they appear.

DAL selected a 10-year planning period for maintenance and rehabilitation/reconstruction budgets. Kimley-Horn evaluated various funding scenarios with airport staff, including no funding, unlimited funding and necessary dollars per year over a 10-year period to eliminate major maintenance and rehabilitation backlog. After reviewing a variety of viable program scenarios, the team recommended a $15 million annual budget as the most cost-effective maintenance and rehabilitation plan for pavement-related improvements. Overall project cost estimates for the recommended 10-year program exceeded $250 million.

Kimley-Horn completed the pavement management program and provided its report in late 2014, just after the Wright Amendment expired in October. That meant that the airport had a good picture of pavement conditions just as its air traffic began to increase.

Fourteen months later, the city of Dallas hired Kimley-Horn to conduct an additional evaluation to determine how pavements were holding up amidst the approximately 80% increase in air traffic over that time period.

Fourteen months later, the city of Dallas hired Kimley-Horn to conduct an additional evaluation to determine how pavements were holding up amidst the approximately 80% increase in air traffic over that time period.

"The pavements had deteriorated at a rate that we did not expect," Nicewander reports. "Having Kimley-Horn back that second time solidified what we were going to have to accomplish over the next five to 10 years. We have a lot of work to do."

Based on the consultant's second evaluation, the airport is currently reevaluating its pavement work priorities, notes Robin Dickens, senior program manager for the Department of Aviation. "It has provided us with the information we need to reprioritize airfield projects going forward. Taken together with the other assessments and the airport master plan, this assessment is a valuable decision-making tool for the airport. It allows us to coordinate upcoming work in a way that makes efficient use of available funding. We can use these findings to lay out a comprehensive program that supports the airport's goals and master plan objectives."

Integrated Approach

While a good pavement management program cannot replace good engineering judgment, it can be an excellent tool to assist airport officials in their decision-making process because the information it provides can be used to prioritize projects and to support funding requests, explains West.

Love Field was unique, he adds, because it performed several other studies concurrently with its pavement management program analysis: an airfield electrical needs study, airport master plan study and airport master drainage study. City officials then instructed Kimley-Horn to integrate the recommendations of these various studies into an overall capital improvement program for the airport that considered all critical project elements.

Edwin Tamang, project engineer for Kimley-Horn, details the value of DAL's method: "This comprehensive approach really pays dividends because it allows city and airport officials to position the airport in context and with full technical justifications for grant opportunities in the future. A lot of airports wait until they have to fix something before they plan for it. That kind of reactive approach doesn't always work out well. Dallas Love Field understood that taking a proactive approach was better because it lines them up for funding well in advance. Drawing from all the evaluations of the different studies and making comprehensive recommendations and decisions based on this holistic picture and not simply pavement condition would serve them better moving forward."

Edwin Tamang, project engineer for Kimley-Horn, details the value of DAL's method: "This comprehensive approach really pays dividends because it allows city and airport officials to position the airport in context and with full technical justifications for grant opportunities in the future. A lot of airports wait until they have to fix something before they plan for it. That kind of reactive approach doesn't always work out well. Dallas Love Field understood that taking a proactive approach was better because it lines them up for funding well in advance. Drawing from all the evaluations of the different studies and making comprehensive recommendations and decisions based on this holistic picture and not simply pavement condition would serve them better moving forward."

Nicewander concurs, adding the comprehensive and proactive approach gives the city and airport a better and more realistic view of the total cost of a pavement project when costs of ancillary projects are considered.

Tamang explains that many airports struggle with initiating projects in an efficient and cost-effective way. It's often difficult for operations and maintenance staff to identify exactly what needs to be done and efficiently integrate projects into work orders, he adds.

With this in mind, Kimley-Horn developed a geographic information system (GIS)-based product that can be integrated with a work-order system.

"Now, airport staff can easily identify a problem area on the airfield using GIS technology on their tablet or smart phone," Tamang adds of the still-to-be-procured system. "If you're out on the airfield in a sea of pavement and you see a problem area, it's tough to nail the location down for others to find it. You can't put a cone or flag out there. With GIS, a problem area can be identified and a work order initiated. It streamlines the process and saves time and money."

Nicewander highlights the executive summary of the pavement management program as particularly valuable. "That's been an extremely helpful tool," she reflects. "It allows us to explain to people who do not necessarily have a technical background at airports why we have to reconstruct a taxiway without bogging them down with technical details."

FREE Whitepaper

PAVIX: Proven Winner for All Airport Concrete Infrastructure

International Chem-Crete Corporation (ICC) manufactures and sells PAVIX, a unique line of crystalline waterproofing products that penetrate into the surface of cured concrete to fill and seal pores and capillary voids, creating a long lasting protective zone within the concrete substrate.

Once concrete is treated, water is prevented from penetrating through this protective zone and causing associated damage, such as freeze-thaw cracking, reinforcing steel corrosion, chloride ion penetration, and ASR related cracking.

This white paper discusses how the PAVIX CCC100 technology works and its applications.