Orlando Int'l Maximizes Taxiway Lighting Efficiency with Advanced Power Supply System

Orlando International Airport (MCO) has a long history of cutting-edge airfield improvements. More than 20 years ago, it was one of the first airports to convert to a computerized lighting control system. Last year, it was the first to install an operational FAA-sponsored runway status light system.

Orlando International Airport (MCO) has a long history of cutting-edge airfield improvements. More than 20 years ago, it was one of the first airports to convert to a computerized lighting control system. Last year, it was the first to install an operational FAA-sponsored runway status light system.

|

factsfigures Project: LED Power Supply & Fixture Replacement Location: Orlando Int'l Airport Site: Taxiway F System Design & Vendor: ADB Airfield Solutions Electrical Consultant: AVCON, Inc. Award: Best Paper for a Technical Presentation, Illuminating Engineering Society Airfield Lighting Conference, October 2010 Of Note: LED power supply reduced energy draw by about 80% |

MCO's most recent upgrade was the installation of an Advanced Power Supply (APS) system to increase the energy efficiency of Taxiway F's LED fixtures.

The airport switched from incandescent to LED fixtures on the taxiway back in 2005 to save maintenance staff from changing lamps every 2,000 hours or so, recalls Frank Barczak, Greater Orlando Airport Authority (GOAA) electrical systems manager.

The airport switched from incandescent to LED fixtures on the taxiway back in 2005 to save maintenance staff from changing lamps every 2,000 hours or so, recalls Frank Barczak, Greater Orlando Airport Authority (GOAA) electrical systems manager.

"The LED system has fulfilled that promise," Barczak emphasizes. Replacing 60-watt incandescents with 7-watt LEDs, however, didn't decrease energy costs as much as expected. "Because we used the infrastructure that was designed for the incandescent lights, a lot of the potential energy savings were gobbled up by the inefficiencies of that infrastructure," Barczak explains. "We decided that there had to be a better way."

Airport authorities turned to ADB Airfield Solutions, which had supplied the LED fixtures back in 2005, for advice. ADB jumped at the opportunity to test its APS system in MCO's rugged environment, which includes high ground water, high temperatures and humidity, frequent lightning strikes, heavy aircraft traffic and interleaved circuits exposed to electromagnetic interference. The installation on MCO's Taxiway F would also be the longest circuit using the APS system.

Minimizing Complexity, Maximizing Efficiency

According to Barczak, the airport achieved its five goals for the new system: minimizing complexity, improving safety, maximizing energy efficiency, maximizing reliability and using existing electrical infrastructure to keep costs down.

"We kept costs down by reusing the existing base can, conduit, cable and connectors," he reports. "We minimized complexity by eliminating half of the parts and pieces under the old system. We increased safety by decreasing the maximum voltage output from 5,000 to 1,000 volts. We maximized reliability by making it a simpler system in which fewer things could go wrong."

system. We increased safety by decreasing the maximum voltage output from 5,000 to 1,000 volts. We maximized reliability by making it a simpler system in which fewer things could go wrong."

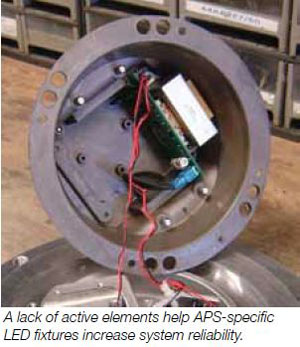

In-pavement and elevated APS fixtures consist of five parts: a ratio transformer, two surge protection devices, a bridge rectifier and the LED. Under the existing 6.6-amp LED lighting circuit, energy was generated via a constant current regulator (CCR) and the electronics placed in each LED fixture converted the 6.6-amp current to a constant electrical current required by the LED lamp. The new system replaces the CCR with an APS that supplies a 2-amp alternating pulse width modulation (PWM) current that feeds the APS LED fixture.

In layman's terms, PWM is similar to the technology used to dim and brighten residential lights. And PWM has been used in other applications since the 1960s, notes Miguel Vasquez-Lavado, ADB's green technology product manager. "It's the most efficient method for driving LED fixtures," Vasquez-Lavado elaborates. "It's a proven and reliable technology."

In more technical terms, the width of the PWM on time at the output of the APS is preprogrammed to comply with the LED dimming curve requirement in FAA Engineering Brief 67. In turn, this eliminates the need for more complex electronics inside the fixture.

"It's a plug-and-play system," Vasquez-Lavado notes. "It allows the airport to reuse its existing base can and conduit system, L-824 cable and L-823 connectors. The system minimizes complexity."

Representatives from AVCON, the company that originally designed and installed the LED system for MCO, believe that the APS system is the best new strategy for maximizing efficiency and savings from LED lighting systems.

Representatives from AVCON, the company that originally designed and installed the LED system for MCO, believe that the APS system is the best new strategy for maximizing efficiency and savings from LED lighting systems.

"Previously, LEDs were adapted to fit the existing infrastructure," recalls Carl Johnson, AVCON senior aviation lighting specialist. "With this new prototype circuit, however, the electrical distribution is made to fit the LED. The result is you achieve the maximum energy benefit from using light emitting diodes. And you're able to reuse everything in the pavement."

Significant Savings

While APS technology may be simple, its savings can be substantial.

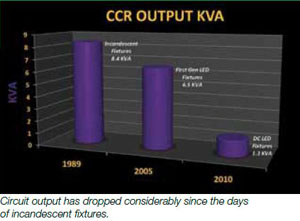

When the original incandescent system was installed on Taxiway F in 1989, the circuit was rated at 13 kVA. Usage dropped to 8.6 kVA when the first-generation LED system was installed in 2005. With the new system in place since August 2010, energy usage has decreased about 80% more to just 1.4 kVA.

rated at 13 kVA. Usage dropped to 8.6 kVA when the first-generation LED system was installed in 2005. With the new system in place since August 2010, energy usage has decreased about 80% more to just 1.4 kVA.

"The new system really simplifies the circuit," Barczak explains. "It just doesn't have to do as much work to illuminate the LED. That's where the savings come from."

Fluctuating utility rates make it  difficult to quantify the savings, but Barczak knows they're accruing. "Even though the utility company raised electricity rates significantly two years ago and we've added close to 5% more lights on the circuit, the costs to run that circuit are considerably lower," he reports.

difficult to quantify the savings, but Barczak knows they're accruing. "Even though the utility company raised electricity rates significantly two years ago and we've added close to 5% more lights on the circuit, the costs to run that circuit are considerably lower," he reports.

The project was funded out of the airport's regular operating and maintenance budget. Costs were fairly minimal because they were worked into the airport's regular preventative maintenance costs for relamping and predictive maintenance.

"While we had to purchase the power supply to replace the CCR," Barczak explains, "we're able to use these parts, as well as the LED fixtures that we had to replace, as spares for other areas of the airport."

Using the airport's own electrical maintenance staff to make the changeover also helped hold down installation costs.

Airfield electrical supervisor Jeff Pace recalls the power supply and fixture changeover as a very smooth process, with 116 in-pavement centerline fixtures being replaced in three nights. "We had a few days of testing and then rolled the system into normal operations," Pace relates. "For the most part, no one noticed, which is a good thing. With airfield lighting, you don't want to give pilots something new to think about."

Airfield electrical supervisor Jeff Pace recalls the power supply and fixture changeover as a very smooth process, with 116 in-pavement centerline fixtures being replaced in three nights. "We had a few days of testing and then rolled the system into normal operations," Pace relates. "For the most part, no one noticed, which is a good thing. With airfield lighting, you don't want to give pilots something new to think about."

Carolyn Fennell, MCO's director of public affairs, reflects on the broader implications of pursuing new technologies: "We feel it's important to keep our costs down without jeopardizing what we call 'the Orlando experience.' We want to have money for flowers and trees. When passengers get on the automated people mover, we want them to feel as if they could be on the monorail at Walt Disney World. Keeping up with new technologies that can cut costs helps us realize this goal."

FREE Whitepaper

Fairbanks International Airport Baggage Transport Conveyor Enhanced With Mod Drive™ System

Airports face a host of unique industry challenges, such as meeting efficiency regulations and seeking out the best maintenance practices to reduce costs and keep operations flowing. In today’s current economic climate, any potential cost savings can go a long way.

In 2019, Alaska’s Fairbanks International Airport (FAI) sought to modernize its equipment and operations. They were dissatisfied with the performance of the gearmotors on their baggage transport conveyors and began searching for new suppliers. Regal approached FAI with a solution that could improve equipment performance and simplify maintenance, with the added benefit of energy cost savings: the Hub City® MOD Drive™ system.

This white paper discusses the hardware deployed, the test results and the annualized expectations for ROI.