In a move that promises to cut mowing to just once a year and reduce wildlife hazards, Erie International Airport (ERI) planted about 95 acres of a special low-growth grass last summer. Although the special species cost about $90,000 more than standard grass, ERI expects to save nearly $800 per acre each year on mowing costs alone.

In a move that promises to cut mowing to just once a year and reduce wildlife hazards, Erie International Airport (ERI) planted about 95 acres of a special low-growth grass last summer. Although the special species cost about $90,000 more than standard grass, ERI expects to save nearly $800 per acre each year on mowing costs alone.

When Airport Manager Chris Rodgers heard a presentation about the patent-pending grass in 2011, he immediately envisioned it for the grounds around ERI's 1,920-foot runway extension. The chance to reap ongoing savings on maintenance expenses was compelling, but Rodgers found the safety implications of discouraging wildlife even more exciting.

"We have an exceptionally high amount of migratory bird activity in the spring and fall," he explains, noting that the airport is located along a busy migratory route for Canada Geese.

|

Project: Low-Growth Grass Location: Erie (PA) Int'l Airport Scope: 95 acres Product: FlightTurf(tm) Manufacturer: Native Return(r) Est. Cost Premium vs. Conventional Grass: $90,000 Installed: Summer 2011 Product History: Developed in 2003 by company specializing in returning ground cover to native plant species Benefits: Requires only one mowing/year; discourages migrating geese from stopping at airport |

Last year, the Pennsylvania airfield logged just two new entries in the FAA's Wildlife Strike Database. In 2010, however, it had eight; in 2009, it had six.

With its runway extension ahead of schedule and under budget, ERI was able to incorporate low-growth FlightTurf(tm) by Native Return(r) into the project. "It was just so intuitive that we knew we had to find a way to use it," explains Rodgers. "This new grass became a significant part of the plan on the ground to discourage wildlife."

ERI's drought-resistant grass is engineered to require little or no mowing. The act of mowing stirs up insects, which in turn attract birds that prey on them. By drastically reducing the need to mow, airports can become far less attractive to birds and reduce aircraft strike hazards, explains Native Return(r) co-owner Christina Kobland.

The special turf is also said to be generally less attractive to insects and their predators. In years of collecting wildlife count data in test plots, Kobland has observed that when birds in adjacent plots of other grasses hop into FlightTurf(tm), they quickly hop back out. Why this occurs, however, is not clear. "It may be endophytic fungal activity or complex plant defense mechanisms at work," she reasons. "I suspect animals find it unpalatable."

Mowing Stand-Down

Personnel at ERI look forward to years of minimal maintenance around the new runway extension. "We need tower clearance to mow in the Runway Safety Area," notes Rodgers. "It is really a frustration."

Kobland adds reduced costs (both equipment and manpower), fewer mowing-related runway closures and lower emissions as other advantages to the company's low-growth grass seed.

Each year, ERI mows its 300 acres of airside grass approximately 20 times between March and November. Although the airport does not record a separate budget line item for mowing, Rodgers agrees with figures from Philadelphia International Airport (PHL), assembled as part of a cost-benefit analysis by Urban Engineers. Based on 2010 dollars and 22 mows per year, Urban calculated that the PHL spends $836 per acre, per year for mowing, not including costs for associated runway closures. "We are not dramatically different from any other airport as far as costs go," says Rodgers.

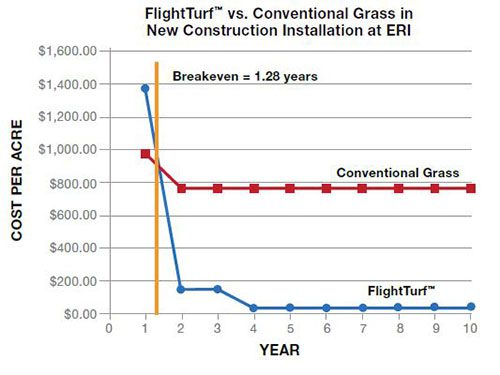

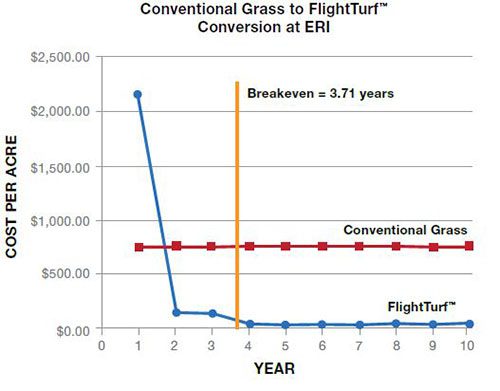

ERI seeded its new grass in two separate contracts. Hill International, the construction management company for the runway extension program, analyzed the second contract, which provided the most accurate comparison of FlightTurf(tm) and traditional grass seed. Kevin Graham, resident engineer with Hill, pegged the cost difference at $968 per acre. But since conventional grass is mowed 20 times more often a year, ERI recoups that premium after 1.3 years, figures Native Return(r) co-owner Wesley Frey.

ERI seeded its new grass in two separate contracts. Hill International, the construction management company for the runway extension program, analyzed the second contract, which provided the most accurate comparison of FlightTurf(tm) and traditional grass seed. Kevin Graham, resident engineer with Hill, pegged the cost difference at $968 per acre. But since conventional grass is mowed 20 times more often a year, ERI recoups that premium after 1.3 years, figures Native Return(r) co-owner Wesley Frey.

Specific price variances will differ from site to site, according to the amount of fertilizer and lime conventional grass would require. As a rule, FlightTurf(tm) requires less of both, notes Frey. Depending on when it is planted, the special low-growth grass might require herbicide treatments during the first three years to kill weeds. Because ERI seeded in mid-summer, it needed herbicides.

Kobland characterizes FlightTurf(tm) as an aggressive grass, noting that it develops into a "monoturf" with no weeds, deep roots and the ability to soak up more runoff than regular grass after its three-year maturation period.

Converting existing turf to the special low-growth species is easy, she adds. "(Crews) kill the existing grass with herbicide, mow it as close to the ground as possible and then slit seed our product into the ground," she explains. "The grass will start to grow in two to three weeks."

The break-even point for turf conversions is a little longer than for plantings on bare soil – about 3.7 years, adds Frey.

On the regulatory front, the FAA does not prohibit airports from using FlightTurf(tm), as noted in a June email to Kobland from Brian Rushforth, manager, Airport Safety and Operations Division Office of Airports Safety and Standards.

Although it will be a few years before Rodgers can assess how much ERI's special grass reduces wildlife hazards or decreases costs, the opportunity to cut mowing expenses even further is attractive. "If we get the results we are expecting from this installation, I could easily calculate a large return on investment for installing this grass elsewhere on the airport," he relates.

Officials at Northeast Philadelphia Airport in Pennsylvania and Greater Rochester International in New York have already made similar calculations and installed the low-growth grass. In addition, the company reports having projects underway or pending at Portland International in OR, Chicago Rockford International in Illinois, Elmira Corning Regional in New York and Maryland's Baltimore/Washington International.

factsfigures

factsfigures