Fort Lauderdale Executive Airport (FXE) has a significant effect on its local economy. According to the most recent Florida Department of Transportation Economic Impact Study, the general aviation facility supports nearly 23,000 jobs and generates $3.9 billion annually. And there’s room to grow.

Aircraft count on FXE’s staff and four fixed-base operators to be available 365 days a year, and the runways to be clear and in good condition. When the main runway (9-27) needed to be repaved, management wanted the project finished as quickly and efficiently as possible. Time, as always, is money; at FXE, it costs millions of dollars per day to be out of service.

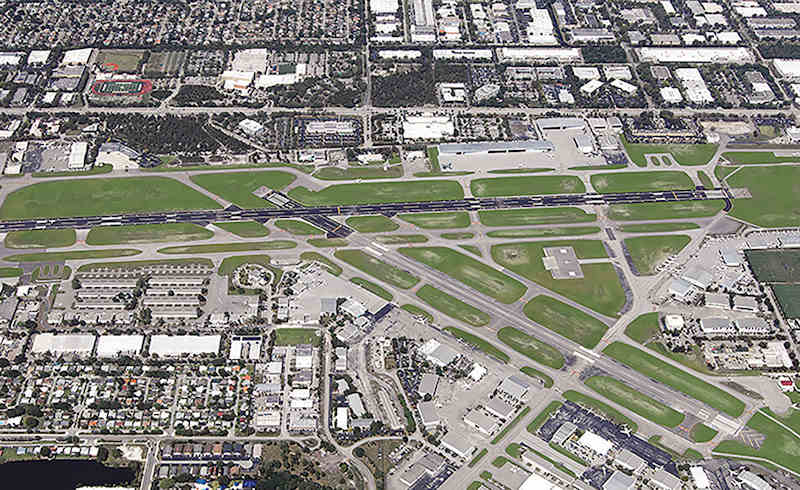

Located approximately five miles from Florida’s Atlantic Coast and six miles north of downtown Fort Lauderdale, FXE is a reliever for Fort Lauderdale-Hollywood International Airport (FLL) and serves as an important jumping-off point for aircraft heading west and south toward the islands.

facts&figures facts&figures

Project: Runway Pavement Rehabilitation Location: Fort Lauderdale Executive Airport, in FL Runway: 9-27 Project Duration: Scope: Resurfacing Runway 9-27 (6,002 ft. long, 100 ft. wide), part of Crosswind Runway 13-31 within 9-27’s safety area & portions of 12 taxiways; updating geometry of intersection of Taxiway A1 & Runway 9-27 Cost: $9.6 million (vs. initial projection of $ 9.7 million) Funding: 90% FAA grants; 5% FL Dept. of Transportation; 5% airport funds Timeline: Bids solicited in early 2024; quotes were returned that summer; contractor cleared to proceed Oct. 15, 2024; construction Feb. 24- March 7, 2025 Engineering & Design: Kimley-Horn & Associates Inc. General Contractor: General Asphalt Co. Inc. Key Benefits: Improved runway conditions |

“We have the Bahamas and the Caribbean in our backyard,” says Airport Director Rufus James. “Clientele who spend time in the Bahamas have homes on private islands, so they often park their jets here and then take a smaller aircraft to the outer islands.”

With a full Customs and Border Protection facility, FXE is an important international point of entry.

To minimize downtime during the recent runway rehabilitation, airport management, engineering consultant Kimley-Horn and contractor General Asphalt set an ambitious goal to get the entire project done in 10 days. Not only was the work completed by the deadline (two hours early, in fact), the team finished $130,000 under budget. All in all, this project was worth celebrating.

Scant Room for Delays

The last time Runway 9-27 received major rehabilitation work was in 2004. That pavement was designed for a 20-year service life and performed as expected. Before the end, however, FXE enacted a plan to maintain safe and efficient use of the runway as it started to show signs of wear.

It was all covered in the airport’s master plan that was approved in 2018. Management knew the runway needed a 1,000-foot extension and a major rehab. After much discussion, leadership decided to prioritize the rehab and pursue the extension later (likely late 2026 or early 2027). Plans for the rehabilitation project were reviewed by the FAA, and the airport sought funding from FAA and the Florida Department of Transportation. The project went out to bid in early 2024, and quotes were received over that summer. By October, the airport issued notice of receipt to the selected contractor, General Asphalt; and work started in February 2025.

Kimley-Horn Vice President Tom O’Donnell led the project, which included resurfacing all of Runway 9-27 (6,002 feet long, 100 feet wide), the part of crosswind Runway 13-31 within 9-27’s safety area, and portions of one dozen taxiways. The geometry of the intersection of Taxiway A1 and Runway 9-27 was also updated to meet current FAA standards.

Completing all of that work in just 10 days was a stretch goal, but a vital one. FXE is perennially ranked as one of the top five busiest general aviation airports in the United States, and it’s often the busiest general aviation airport in Florida. The margin for delays was paper thin.

“We serve a variety of small to larger business aircraft operators that expect a continuous level of service and access,” James notes. “We strive to ensure that the airport is readily available with minimal impacts to daily operations.”

Laying Out All the Cards

James and O’Donnell both knew the stakes quite well. In an interesting coincidence, O’Donnell was a new hire at Kimley-Horn in 2000, when James started working for the airport; and the previous repaving of Runway 9-27 was one of O’Donnell’s first big airport projects.

“I was a young engineer brought into the project for construction observation, so I was able to see what lessons were learned in that period of time,” O’Donnell recalls. “I was able to implement those lessons for this go-around; this project was nearly the same scope of work.”

“I was a young engineer brought into the project for construction observation, so I was able to see what lessons were learned in that period of time,” O’Donnell recalls. “I was able to implement those lessons for this go-around; this project was nearly the same scope of work.”

He likens his early days on the job to “drinking from a fire hose.” One of the most striking lessons he learned, and has remembered for the last two decades, is the importance of determining a contractor’s limits for completing a given project. O’Donnell knew there would be little room for error this time at FXE with a 24/7 schedule for 10 straight days, and therefore considered it critical to understand exactly how to pivot if needed.

Kimley-Horn brought in three contractors to review the runway project documents and discuss the feasibility of the desired timeline. While none of the firms were guaranteed the job, each offered valuable feedback about how to sequence the work, explains O’Donnell.

He and James both cite preparation and communication as huge factors in the ultimate success of the project.

“If you enter a job haphazardly, then you can expect a lot of snap moves, a lot of delays and a lot of change orders,” James says. “First and foremost is communication; I think it’s really critical.”

“If you enter a job haphazardly, then you can expect a lot of snap moves, a lot of delays and a lot of change orders,” James says. “First and foremost is communication; I think it’s really critical.”

O’Donnell completely agrees.

“The engineering itself is the price of admission,” he remarks. “You need to understand how the airport operates. What’s its DNA? What kind of clientele does it serve? What are the goals of the airport? If you only understand the engineering, you can create a big problem at an airport.”

Don’t expect contractors or consultants to read your mind, James adds. Communicating, establishing deadlines and dates, and ensuring everyone knows exactly what is going on are mandatory steps, he emphasizes.

“You have to lay out the deck of cards entirely on the table, so you know what is dealt to you,” says James.

Narrowing the Window

Anyone who has lived in Florida or spent a fair amount of time there knows that pop-up showers are frequent from May to November, and hurricanes are often a possibility, too. The project team had to thread the needle when scheduling to avoid precipitation as much as possible, because inclement weather could devastate the whole project.

Planners identified periods when the weather was most likely to be favorable and then layered on data about when FXE typically experiences the least activity, down to the exact amount of fuel purchased on each day of the year. It was a Venn diagram with only a tiny overlap. January and February emerged as the best targets, and the project team narrowed that window to late February.

Ironically, it rained the very day work was set to begin. Fortunately, the airfield didn’t have to be cleared until later that night.

On Feb. 24, 2025, at 10:00 p.m., the clock started ticking for the prescribed 10 days. Resurfacing work was scheduled in phases, with Phase 1 focusing on the eastern part of the main runway, Phase 2 on the middle section (which required the main and crosswind runways to close concurrently), and Phase 3 finishing on the west end.

Crews worked around the clock to repave and apply new markings to Runway 9-27.

With backup equipment in place as a contingency, the contractor started milling.

“The team was ready to work around the clock, even preparing with backup crews,” James recalls. “The workers knew what they had to do, and there wasn’t any slacking off. Everyone understood what their role was.”

Just Ahead of Schedule and Under Budget

Because some airport tenants travel to the Bahamas on a daily basis, FXE kept its 4,000-foot crosswind runway (Runway 13-31) open during most of the project. However, it didn’t meet the needs of all jet operators, especially for those traveling greater distances. With that in mind, the project team shut down the intersection of 13-31 and 9-27 on a Friday evening, knowing work had to proceed without a hitch.

As scheduled, Runway 13-31 was back to business by 6 a.m. Monday morning, and it went without the remaining work continued.

In the end, the project was completed slightly ahead of schedule—a notable accomplishment with such a tight timeframe. Construction was set to be completed by 6:00 a.m. on Friday, March 7, 2025, with the main runway opening immediately thereafter. The contractor finished by 4:00 a.m., two hours early. With that extra time, airport operations staff actually had time to spare after inspecting the runway for foreign object debris and running through the post-project safety checklist.

The team also came in slightly under budget. At the start, the job was estimated to cost $9.75 million but finished at $9.62 million.

“You hope and pray everything goes well: that there are no safety issues, no security issues, no delays,” James says. “Each day that went by, we checked with the engineer and consultant. And it finished as smoothly as we’d hoped.”