In 2018, Washington state mandated the phased elimination of per- and polyfluoroalkyl substances (PFAS) in firefighting foam for anything other than emergency response. That ruled out its use by airport crews for training or equipment testing. PFAS, which have long been used in firefighting foam because of their effectiveness, are also now known for their harmful effects on people, wildlife and the environment.

The new state legislation presented a challenge for Randy Krause, Port of Seattle Fire Department chief, because at that time FAA required airports to use fluorine-containing foams.

The new state legislation presented a challenge for Randy Krause, Port of Seattle Fire Department chief, because at that time FAA required airports to use fluorine-containing foams.

That changed in October 2023 when the U.S. Department of Defense approved a fluorine-free foam that met FAA’s rigorous standards, previously achievable only with aqueous film-forming foams (AFFF), which contain PFAS. That cleared the way for airports like Seattle-Tacoma International Airport (SEA), which the Port of Seattle operates, to transition to a safer and more environmentally friendly fluorine-free alternative.

Aviation Senior Environmental Program Manager Megan King, who manages the Port’s aviation-related contaminated sites program and partnered with Krause in the transition process, underscores the benefits of this important milestone. “The primary benefit to us is removing a potential point of exposure to people who work here at the fire department, people who work more broadly at the airport and also the traveling public,” she says. “The second benefit is the environmental benefit of not putting this toxic material into the environment where it can contaminate soil, groundwater and surface water runoff that could potentially migrate away from our property.”

| facts&figures

Project: Cleaning Residual PFAS from Firefighting Vehicles Component of: Transition to Fluorine-Free Location: Seattle-Tacoma Int’l Airport, in WA Distinction: 1st U.S. airport to use soap-based Cost: $50,000-$70,000/vehicle Budget: $600,000 Funding: Airport; potential FAA grant reimbursement Timeline: June–August 2024 Product Used: PerfluorAd Provider: TRS Group ARFF Vehicles: 2 Oshkosh Striker 3000s, Water Testing: Analysis of PFAS in first rinse water, final rinse water & treated rinse water discharged to sewer Waste Disposal: Treated rinse water is discharged to sanitary sewer; solid waste (PFAS sludge) from treatment process is sent to non-hazardous landfill or hazardous waste incineration facility, per test results Key Benefits: Reducing PFAS exposure risk for firefighters, airport personnel & general public; minimizing release of harmful PFAS to the environment |

Here’s the Hitch

Before SEA could start using the new fluorine-free foam, the airport needed to clean its five aircraft rescue and firefighting (ARFF) vehicles to eliminate any residual product that contained PFAS. That process involved several critical steps. The first was determining “How clean is clean?”

The answer was elusive, given a prevailing lack of industry standards or mandated benchmarks. “We didn’t really have any criteria,” King explains. “We were trying to do this work without having a specific end goal.”

So, SEA personnel asked cleaning solution providers to tell them what was possible, and then evaluated the various options based on effectiveness, waste generation and process length.

From Krause’s perspective, the top two priorities were getting the ARFF vehicles as clean as possible and generating the least amount of waste. Although six of the seven U.S. airports that have already transitioned to fluorine-free foam used a water-only rinse process, Krause wasn’t convinced that was enough. He offers the analogy of washing dirty dishes. A rinse with cold water will get the dishes somewhat clean, but you wouldn’t want to eat off them. Rinsing with hot water is a bit better. But hot water and soap do the job right. In this case, the “soap” SEA selected is PerfluorAd, a biodegradable plant-based solution provided by TRS Group, founded in Washington state.

Krause expresses confidence in the choice based on his team’s research and documented performance at European airports and in other industries. “We’re very happy with the data for this product,” he says. “It’s in the realm of 99% effective on most of the PFAS chemicals that were evaluated. In the testing we’ve done so far, we’re at 99% clean in our trucks, plus or minus a little bit.”

Separating the Sludge

David Fleming, founder of TRS Group, elaborates about the chemistry that drives the product: “PerfluorAd is a surfactant, an oleic acid, plant-based soap. It is a positively charged molecule, and the PFAS is a negatively charged molecule. When those two come into contact, they form particles through a weak but stable ionic bond that can be sedimentated.”

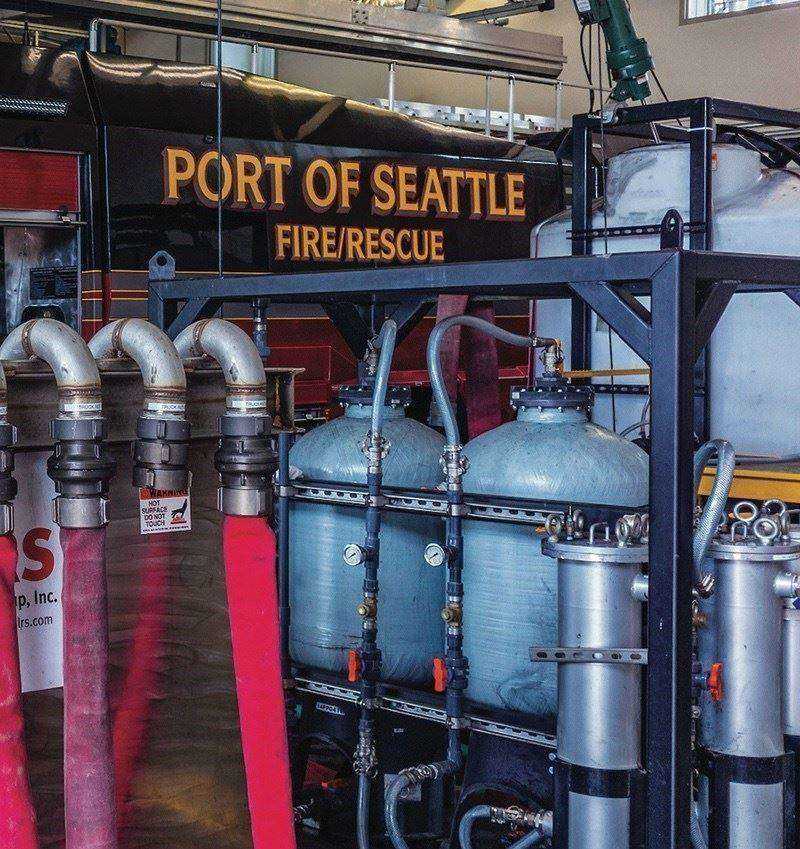

The cleaning process begins by removing PFAS-containing concentrate from vehicles, followed by a rinse with cold potable water. The rinsate is captured and tested to evaluate the baseline concentration of what remains in the trucks. Next, PerfluorAd concentrate is mixed with potable water heated to 110 to 120 degrees Fahrenheit. TRS personnel flush the solution through the firefighting vehicle three to five times. When there’s no more visible foam formation, they conduct a final potable water rinse and analyze the captured rinsate.

Technicians from TRS worked with airport staff to devise a special process for cleaning the complicated inner systems of the ARFF vehicles. They created a flow path that accessed the various channels and piping that feed the hoses, lines, turrets and nozzles. “David [Fleming]’s team on the ground worked with my mechanics to manipulate and trick the vehicles to create the flow path they wanted to take advantage of that processing,” says Krause.

The process uses flocculation, sedimentation and filtration to remove particles from the water. The remaining sludge is disposed off-site, and the water continues to be filtered until it’s clean enough to be discharged on site into the sewer. Fleming says it’s a new application for a process that’s been used for decades in the municipal wastewater treatment industry.

In general, cleaning ARFF vehicles requires large volumes of water, and airports that rely on water-only rinses have to deal with that contaminated water. Krause considers it a huge advantage that the PerfluorAd process also cleans the wastewater. “We probably would have had 70,000 to 90,000 gallons of wastewater that we would have had to pay to dispose of if we couldn’t discharge on site,” he says, estimating disposal fees of more than $5 per gallon. “This process really pays for itself with the waste mitigation.”

In general, cleaning ARFF vehicles requires large volumes of water, and airports that rely on water-only rinses have to deal with that contaminated water. Krause considers it a huge advantage that the PerfluorAd process also cleans the wastewater. “We probably would have had 70,000 to 90,000 gallons of wastewater that we would have had to pay to dispose of if we couldn’t discharge on site,” he says, estimating disposal fees of more than $5 per gallon. “This process really pays for itself with the waste mitigation.”

The airport chose to clean its ARFF vehicles at a cost of $50,000 to $70,000 each rather than purchase new ones for $1.2 or $1.3 million each. The project team secured $300,000 for cleaning and another $300,000 for the new fluorine-free foam product through SEA’s internal budget process. King hopes the expenses qualify for some reimbursement from the FAA Reauthorization Bill recently approved by Congress, once that funding is appropriated.

Blazing a New Trail Together

Krause set this change in motion back in 2018 when he stood up in front of 400 people at a conference and announced SEA would be the first U.S. airport to transition to fluorine-free firefighting foam. “I did it to throw down the marker,” he says. “But I’ve I followed up with that, asking to be invited to the table. We are the first to transition [using a cleaning technology], as I had always thought it should be. I’m very proud and confident of that.”

Extra precautions are taken to capture stray rinsate while vehicles are being cleaned.

King largely attributes the airport’s smooth transition to strong collaboration with the Port of Seattle, TRS Group and various industry stakeholders. “I think the reason we were able to be successful is that we had a good meld of personalities who were not going to take no for an answer—plus having support from our leadership. We really never faced resistance,” she comments.

Fleming also praises the partnership, and refers to Krause, King, SEA and the Port as leading forces for fluorine-free foam. “They are the visionaries bringing this forward and doing everything they said they would do,” he says. “I just find it inspiring, frankly, to be part of this team and to have the opportunity to work with them.”

King acknowledges the industry backing SEA received, especially the environmental and firefighting communities. “We’ve had a lot of input, a lot of support and a lot of really good guidance from other people in our same situation at other places,” she explains. To enhance what they have learned and help other airports transition from PFAS products, King and Krause are involved with industry groups. King works with the American Association of Airport Executives (AAAE) Environmental Services Committee, and Krause sits on the FAA Advisory Committee. Both contribute to the PFAS working group of Airports Council International.

Looking ahead, Krause notes that SEA has plans for ongoing monitoring and evaluation to help ensure the long-term success of its transition to fluorine-free foam. One potential issue is the persistent nature of PFAS. “It gets into all the nooks and crannies, so there’s a concern about it “rebounding,” meaning that whatever traces were left on the walls or piping could leach into the new foam product,” he explains. To enhance confidence, King’s team will run tests after the fluorine-free foam has been in SEA’s trucks for two months, and those results will help determine the frequency of subsequent testing.

The airport also is preparing to share its findings and experiences with the broader aviation community, serving as a “been-there-done-that” resource for other airports navigating their own transitions.

To that end, Krause and King offer valuable advice about their process. Krause emphasizes the importance of prioritizing safety. “Eliminating a potential exposure for my firefighters is my No. 1 priority, and the best way to do that is to use cleaning technology that will get it as clean as possible. It’s as simple as that.”

King advocates taking a proactive approach: “Don’t be scared to do it. Talk to people who’ve been there.” She also encourages airport leaders to adopt a big-picture mindset. “Think longer term about what kind of risks you still carry if you don’t do the best that you can [to eliminate PFAS]. The less you spend now, the more risk you’re carrying with you into the future for things that will end up costing you way more.”