|

|

Southwest Florida International |

“It was something we didn’t necessarily want to be first in, but because we were designing a new terminal, we recognized that we needed an inline system in light of 9/11,” explains aviation division director Gary Duncan.

The 15,000-linear-foot system with 41 power faced diverters and seven in-line L-3 Communication Units did, in fact, present its share of challenges.

|

Facts and Figures Project: Baggage Hygiene Training Location: Southwest Florida International Airport Airport Operator: Lee County Port Authority Video-based Training Consultant: Elite Line Services Computer-based Training Consultant: The American Association of Airport Executives Result: Average bag error rate dropped from 4% – 5% before training and system modifications to 1% – 11/2% afterward |

“Within that first year, we learned that the system was not working according to plan, and needed a major modification,” Duncan says, noting a $13 million recirculation belt addition at the tail end of the initial ELS contract. “So during that second year of operation, we not only had to modify the system, but we here at the Port Authority elected to maintain it. As it was described to me, it was very similar to trying to fix the transmission on your car while you’re driving it.”

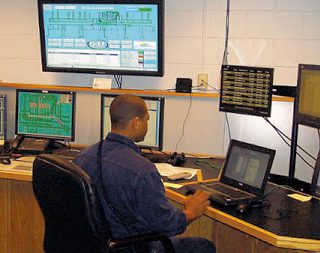

The Port Authority quickly learned that maintaining a sorting and screening system was not a “core competency” and approached ELS to operate and maintain the system once again. In August 2007, a new two-year contract that included manual encoding, pier running and functions such as control room operation and jam clearing took effect.

“After the system was fully modified, we brought ELS back and put our maintenance staff back in the terminal and the airfield where they were originally hired to work,” Duncan explains. “Since that time, the system has been running great and ELS has been doing everything according to the contract.”

Clean Start

When the Port Authority asked ELS to reassume maintenance responsibilities, it had several goals in mind. Its list included traditional objectives such as increasing reliability, enhancing cost savings and improving service to carriers and passengers. It also included a somewhat unusual element. It asked ELS to develop training programs for the airlines about proper bag induction.

“One of the things Lee County recognized was a need for the airlines to train in the proper techniques for ‘bag hygiene,'” explains ELS regional director Boyd McKenzie.

“One of the things Lee County recognized was a need for the airlines to train in the proper techniques for ‘bag hygiene,'” explains ELS regional director Boyd McKenzie.

In order for the inline system to operate properly, bags must be “clean” when they are sent into the system – wheels up, unnecessary straps removed, etc. Bad bag hygiene by one airline can cause baggage delays for all airlines utilizing the system.

The training program developed by ELS in conjunction with the Port Authority measurably improved system performance. Average bag error rates have dropped from 4% to 5% before training and system modifications to 1% to 11/2% afterward.

|

|

The training is not optional. By rolling video-based refresher courses into its badging program, the Port Authority ensures that existing employees are reminded regularly about proper bag handling techniques.

“We needed to come up with a better way to educate the users of the system as opposed to constantly reminding them about the rules of how to put a bag in,” Duncan explaines. “Everyone that touches a bag – skycaps, airline ticket representatives, airline managers, Port Authority staff involved with the baggage system and ELS staff – goes through it once a year on their anniversary hire date when their security badges are renewed. If employees don’t go through the baggage training, they don’t get their new badge.”

Last year, more than 200 people were trained on proper bag hygiene. Duncan attributes a considerably lower jam rate with improved bag hygiene techniques taught in the training program.

Phase 2

Currently, the Port Authority and ELS are evolving the video-based training module into a custom computer-based training program with the help of the American Association of Airport Executives (AAAE). Electronic Computer Instructional System and Training Management, or eCISTM, is a Web-based, open architecture learning management system developed by AAAE.

“A number of airports are using it for SIDA (Security Identification Display Area) and driver training, but we may be the only ones using it to date for baggage training,” reports Duncan.