When it comes to runway renovations and other projects, officials at general aviation airports in Colorado are especially fortunate, because the state regularly offers proactive financial and technical assistance. The Division of Aeronautics, a branch of the Colorado Department of Transportation, makes resources available to many of the state’s 74 public use airports.

When it comes to runway renovations and other projects, officials at general aviation airports in Colorado are especially fortunate, because the state regularly offers proactive financial and technical assistance.

The Division of Aeronautics, a branch of the Colorado Department of Transportation, makes resources available to many of the state’s 74 public use airports. “We are 100% funded by state aviation fuel taxes, and most of that money goes right back to the airports,” says David Ulane, the division’s director.

The Division of Aeronautics, a branch of the Colorado Department of Transportation, makes resources available to many of the state’s 74 public use airports. “We are 100% funded by state aviation fuel taxes, and most of that money goes right back to the airports,” says David Ulane, the division’s director.

“Our total revenue is roughly $33 million a year, and about two-thirds of this money is reinvested every month back to each airport where fuel is sold, depending on how much tax revenue that facility has earned. The individual airports can decide how to use it, so as long as they do so only for aviation purposes on the airport,” explains Ulane. “Most of the remaining third of our revenue we invest back into airports through grants to airports for various projects including pavement maintenance, if they request such funds. Some of the remaining third also goes to the U.S. Department of Agriculture, for wildlife management on airport properties and other statewide initiatives.”

|

Project: Pavement Restoration Assistance Program Location: 74 public general aviation airports in Colorado

Sponsoring Organization: Colorado Div. Annual Revenue: $33 million Reimbursement to Airports for All Projects: $22 million annually (approx.) Total Grant Funding to Airports: $6 million (approx.) Key Benefits: Financial assistance for pavement projects; detailed pavement inspections on 3-year rotation; detailed online reports with pavement condition index scores & other various airport improvements. |

Each airport chooses the type of pavement or product it wants to use and the vendors it wants to work with, he emphasizes. The Division of Aeronautics, in turn, performs pavement inspections of each airport every three years. A comprehensive inspections report, including pavement condition index results and other details, is continually updated and available for any airport manager to review. “We are available to answer any questions they may have,” Ulane comments. “We don’t recommend specific products, per se, but do encourage our airports to touch base with their colleagues from other airports that might share similar conditions in climate, altitude or other factors.”

Traveling to all of Colorado’s general aviation airfields to collect pavement condition data can be a challenge, given the state’s unpredictable climate and mountainous terrain. “The inspections are usually done in summer,” says Ulane. “We have a staff of eight people, and three are aviation planners. Generally, our people cover two or three airports in one trip. For large-surface airports such as Colorado Springs, it can take two full days. For small airports, in might only take half a day.”

The state’s time and effort reap valuable benefits, says Brad Grose, managing director at Asphalt Systems Inc. (ASI). The company sells asphalt preservation products throughout the world. Being familiar with programs elsewhere, Grose believes Colorado has one of the best pavement and inspection and inventory programs in the United States. “They maintain an incredible database of each airport’s pavements, including taxiways and runways,” he says. “All data is available on the state’s website, and this is an invaluable resource for any airport manager considering a new project.”

Climate Challenges

Colorado’s weather puts airfield pavement through the ringer. Ulane recalls the challenges he experienced as an assistant airport director at Aspen/Pitkin County Airport, which is at 8,000 feet: “It can be 80 degrees in summer. At high altitudes, there is more sun damage, since the sun’s intensity is greater. Then in winter, Aspen might get 200 inches of snow a year. I remember we had to perform a great deal of pavement maintenance. Snowplows also damage runways, since they are used so frequently.”

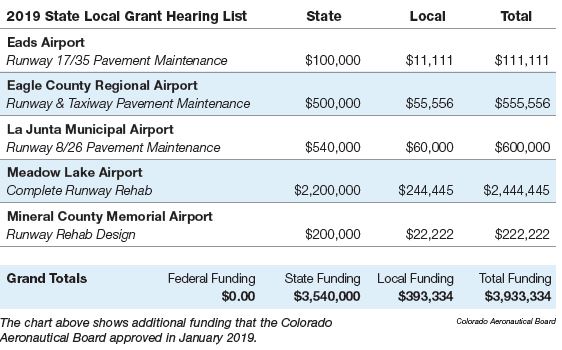

Since pavement resurfacing projects are continually in the pipeline throughout the state, Ulane was very pleased that the Colorado Aeronautical Board added an additional $3.54 million in January 2019, just for pavement maintenance and rehabilitation. “Division staff, our board and the FAA are excited about that,” he says. (See chart on Page 41 for information about which airports received funds.)

The Division of Aeronautics encourages all eligible airports in the state to apply for grants to help pay for pavement maintenance projects. “We are a funding entity, so we tell our airports: ‘Take care of what you have so that everyone’s limited resources will go further, ’” Ulane remarks.

Rifle Airport

One airport executive who has taken full advantage of the state’s assistance is Brian Condie, director at Rifle Garfield County Airport (RIL). “We are very diligent in our pavement maintenance,” Condie reports. “We have only one main runway, Runway 8-26, and it is busy; we had about 24,000 annual operations in 2018. About 90 percent of our traffic comes from private jets. We sell the third-most amount of jet fuel of any general aviation airport in Colorado—about 1.5 million gallons in 2018.”

Two factors drive RIL’s strategy. “First, we feel we save money by spending money now on preventive maintenance, rather than having to completely rebuild our runway like we did in 2010,” Condie explains. “Second, due to our somewhat high-end clientele, image is important. We want to keep our runway, taxiways, lights and buildings in great condition, since it shows our customers that everything is well maintained. We also repaint the runway every other year.”

Two factors drive RIL’s strategy. “First, we feel we save money by spending money now on preventive maintenance, rather than having to completely rebuild our runway like we did in 2010,” Condie explains. “Second, due to our somewhat high-end clientele, image is important. We want to keep our runway, taxiways, lights and buildings in great condition, since it shows our customers that everything is well maintained. We also repaint the runway every other year.”

Condie has received state funding for multiple projects. “After we rebuilt our main runway in 2010, the Division of Aeronautics recommended that we do our first fog seal four years later. Then, as they suggested, we did our next fog seal in 2018,” he relates. “In addition, we do weekly inspections of our runway for cracks.

So far, our pavements have held up extremely well since last summer’s work.”

Condie closely monitors the products used by other airports in the region. “We asked the state for information about what asphalt product other airports in our area have used successfully, since the state inspects all the surfaces. In our case, we decided to go with ASI’s GSB-88.”

With only one runway, it was important to minimize disruption when that runway had to be closed for resurfacing. “When we did the fog seal in 2018, we did the entire airfield. We spent one day doing the fog seal, and two days applying the first coat of paint. We did the second coat of paint six weeks later. In all, we had to close the airport for about four days,” he recalls.

Advance planning was the key to minimizing disruptions. “We sent out NOTAMs well in advance; we tried to give all our clients and pilots two months of advance notice,” Condie explains.

“We also made sure our construction dates did not conflict with other big events in our area. For example, Atlantic Aviation is our main FBO, and they sponsor a couple of big events every year. We made sure our scheduled runway work did not conflict with those.”

Although RIL has used state funds for pavement projects in the past, the airport paid for all the pavement maintenance completed last year itself. Total cost was about $435,000. “The reason for that was that we needed to spend about $800,000 in 2018 for snow removal equipment, and the Division of Aeronautics told us they would provide more funding for that,” Condie explains.

In retrospect, he is pleased that the pavement work is over and has been well received. “We have been given excellent feedback from the pilots. The pavement surfaces and the lights are all in excellent condition. We should not have to do another resurfacing until 2023.”

Rangely Redesignates Main Runway

Another airport that has benefited from Aeronautics Division funding is Rangely Airport. “They have helped us in the past with various resurfacing projects, and this year we expect to ask them for funding help in another area,” says Airport Manager Jason Krueger. “We will have to change our main runway designation from 6-24 to 7-25, due to variations in magnetic readings. We have a flight school here, and 98% of our 10,000 annual operations come from that school. This is a safety issue, especially with lots of student pilots. We will also need new signs.”

In five years, the airport will need to move its main taxiway about 100 feet south because it is too close to the runway and does not meet B2 standards. “This will be a big project that will take a substantial amount of time and money,” says Krueger. “We will hopefully get help from the state on that project as well.”

Supplier Offers Assistance

One of the most popular products used by Colorado airports is GSB-88, manufactured by ASI. “Our role is material supplies; we do not install any product,” Grose specifies. “If airport managers or their engineers need more information from us, we are, of course, happy to oblige. We are very committed to the aviation industry, and are always happy to help find pavement solutions for airports, even if that means recommending other suppliers’ products if they are better suited to the need. We like being the ‘go to’ company for pavement preservation or problem solutions here in the United States.”

One of the most popular products used by Colorado airports is GSB-88, manufactured by ASI. “Our role is material supplies; we do not install any product,” Grose specifies. “If airport managers or their engineers need more information from us, we are, of course, happy to oblige. We are very committed to the aviation industry, and are always happy to help find pavement solutions for airports, even if that means recommending other suppliers’ products if they are better suited to the need. We like being the ‘go to’ company for pavement preservation or problem solutions here in the United States.”

Often, ASI sends technical employees to assist with pavement projects. “If someone decided to use our product, we will work closely with the contractor chosen for the job,” explains Grose. “If the airport or contractor requests our presence, we are happy to send one of our representatives on site to assist. Most of our customers do take advantage of that service.”

facts&figures

facts&figures