Effective strategies to reduce aircraft noise must be based on accurate information. Whatever the strategy, precise information is always the starting point. To collect the best possible noise data about Minneapolis-St. Paul International Airport (MSP), the Metropolitan Airports Commission developed a machine learning technology that received a U.S. patent in late February 2023.

Effective strategies to reduce aircraft noise must be based on accurate information. For example, is the noise, in fact, coming from aircraft? How loud is it? When and where does the noise occur? Knowing the answers to such questions can yield targeted responses and preventive measures, and help to communicate with residents.

Whatever the strategy, precise information is always the starting point. To collect the best possible noise data about Minneapolis-St. Paul International Airport (MSP), the Metropolitan Airports Commission developed a machine learning technology that received a U.S. patent in late February 2023.

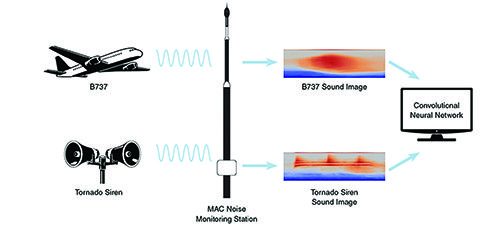

Paraphrasing the patent, the Airport Noise Classification Method and System receives data about noise events captured by a set of geographically distributed noise sensors. Each event corresponds to noise that exceeds an established threshold. The system classifies events as either aircraft noise or non-aircraft noise.

|

Project: Airport Noise Classification Method & System

Location:

Developer: Runways: 4

2022 Passenger Volume: 2022 Operations: 310,235

Technology Development: Patent Application Process: 2018-2023 Patent Issued: Feb. 2023 Strategy: Develop & patent a machine learning system that analyzes & classifies sound data gathered by sound level meters already in key locations under airport flight paths Co-Inventors: Matt Baker, Brad Juffer & Derek Anderson from Metropolitan Airports Commission; University of Minnesota doctoral candidate Nicholas Heller Additional Support: Legal Affairs & Information Technology departments of the Metropolitan Airports Commission |

Brian Ryks, chief executive officer of the Metropolitan Airports Commission, notes that the project that developed the system was about more than technology. “[Our] employees are committed to continuous improvement and innovation, and this project highlights our team’s drive to advance decades-long efforts of working with community stakeholders, airport users, the FAA and other government entities to address noise issues,” he explains.

The need for new technology stands to reason. While aircraft engines are significantly quieter than years ago, aircraft noise continues to be a matter of concern for airports, communities and airport authorities. Noise impacts quality of life, community and government relations and potentially even airport economics. “Quiet flying is good business,” is how the National Business Aviation Association put it in the group’s noise abatement program manual for airports.

Many airports, especially those in metropolitan areas such as Minneapolis, Los Angeles, Seattle, Boston and Miami, have had comprehensive noise abatement programs for years. Often, politicians get involved. Last year, for instance, lawmakers announced $4 million in federal funding to provide noise mitigation measures for 220 residences near Baltimore/Washington International Thurgood Marshall Airport.

Multi-Pronged Approach

MSP’s noise program, established in the 1960s, has evolved into a set of various mitigation and abatement initiatives. Key elements include regular meetings of a noise oversight advisory board with community and industry stakeholders; organizing and prioritizing runway use to move aircraft activity over less-populated areas; and regularly monitoring noise and operations.

Since 1992, MSP’s noise mitigation program has invested more than $510 million to acoustically retrofit about 15,000 single-family houses, 3,300 apartments and 19 schools near the airport. The program uses FAA Aviation Environmental Design Tool to develop annual noise contours. Residential sound insulation improvements typically include new windows, doors and insulation for walls and roofs.

Last April, MSP announced it is extending the noise mitigation program in a new phase to run from 2025 to 2032. Approvals for the extension came from three local cities, the Minnesota Housing Authority, and a county court and the FAA. The entities’ original agreement with the Metropolitan Airports Commission established the phase of the program that began in 2007.

Deciphering Decibels

The complex process to create and patent advanced noise measurement technology is yet another component of continuing noise mitigation efforts at MSP. A diverse team from the Metropolitan Airports Commission started developing the technology in 2016 and finished in 2018.

“Experts in acoustics, computer science, GIS (geographic information systems) and aviation collaborated and brainstormed together to arrive at the final solution,” says co-inventor Brad Juffer, who was manager of Community Relations for the Commission at the time. The system, he explains, addresses a key point: We have a sound. Do we have an airplane? The team’s system classifies each sound event that occurs at and near the airport, particularly under flight paths. “With this classification system, we gain more reliable data to better understand overall trends impacting our airport neighbors,” says Juffer.

Michelle Ross, current manager of Community Relations for the Metropolitan Airports Commission, adds that the technology used at MSP “provides reliable data that we can share with residents, use to educate our pilot community and manage noise abatement and mitigation activities in a manner that is mindful of our communities.”

Michelle Ross, current manager of Community Relations for the Metropolitan Airports Commission, adds that the technology used at MSP “provides reliable data that we can share with residents, use to educate our pilot community and manage noise abatement and mitigation activities in a manner that is mindful of our communities.”

The new system works with and reviews data from noise monitors already in place, including the airport’s 39 Larson Davis Model 831 sound level meters.

“The backbone of the classification system is existing technology that converts an audio file of a sound event into a picture,” Juffer explains. “For instance, the sound image of a Boeing 737 will have a very different image compared to a neighborhood tornado siren.” The images are fed into a convolutional neural network, which is a computing capability that analyzes and recognizes visual images. The network then “learns” from an archive of known aircraft sound images and classifies future data as aircraft or non-aircraft events.

Ross reports that the system is working as expected, and is accurately identifying aircraft noise.

Patently Effective

With the new network up and running at MSP in 2018, the process to patent the technology began. The Metropolitan Airports Commission filed an application in October 2019, and the U.S. Patent Office issued a patent (No. 11,593,610) on Feb. 28, 2023. Three of the four inventors listed were with the Airports Commission: GIS Solution Architect Matt Baker; Juffer, who now serves as assistant director, Operations Optimization; and Derek Anderson, an acoustics and data analysis coordinator who has since left the organization. The fourth co-inventor was Nicholas Heller, a computer science and engineering doctoral candidate from the Computer Science Department at the University of Minnesota.

With the new network up and running at MSP in 2018, the process to patent the technology began. The Metropolitan Airports Commission filed an application in October 2019, and the U.S. Patent Office issued a patent (No. 11,593,610) on Feb. 28, 2023. Three of the four inventors listed were with the Airports Commission: GIS Solution Architect Matt Baker; Juffer, who now serves as assistant director, Operations Optimization; and Derek Anderson, an acoustics and data analysis coordinator who has since left the organization. The fourth co-inventor was Nicholas Heller, a computer science and engineering doctoral candidate from the Computer Science Department at the University of Minnesota.

While other airport entities have also earned patents (see sidebar on opposite page), it is not a common occurrence. “It’s exceptional for airport operators to develop new inventions, so the U.S. patent is quite an accomplishment,” says Evan Wilson, deputy general counsel for the Metropolitan Airports Commission.

The application required “rigorous legal documentation defining what the technology is, what it does and how it is leveraged in [our] system,” says Juffer. “The patent process took longer than developing and implementing the technology itself.”

Technology notwithstanding, Ryks highlights how the patent reflects Metropolitan Airports Commission values, specifically those that foster innovation and continuous improvement. In fact, he and other Commission leaders believe there may be more viable avenues for the patented system in the future, both at MSP and possibly beyond. Along that line, they are looking into possibly patenting the technology in Canada. As Wilson adds, “We’re excited for the technology’s potential and are just now exploring how we could assist or share this with other airports or industry partners.”

Technology notwithstanding, Ryks highlights how the patent reflects Metropolitan Airports Commission values, specifically those that foster innovation and continuous improvement. In fact, he and other Commission leaders believe there may be more viable avenues for the patented system in the future, both at MSP and possibly beyond. Along that line, they are looking into possibly patenting the technology in Canada. As Wilson adds, “We’re excited for the technology’s potential and are just now exploring how we could assist or share this with other airports or industry partners.”

Stay tuned.

facts&figures

facts&figures