Philadelphia International Airport (PHL) has embarked on an initiative to calibrate and quantify the impacts of sustainable design and construction throughout its facilities. Using a formalized framework for assessing sustainability, resiliency and equity in civil infrastructure, PHL is contributing to a sea change in the way infrastructure is understood by the people who understand it best.

Philadelphia International Airport (PHL) has embarked on an initiative to calibrate and quantify the impacts of sustainable design and construction throughout its facilities. Using a formalized framework for assessing sustainability, resiliency and equity in civil infrastructure, PHL is contributing to a sea change in the way infrastructure is understood by the people who understand it best. A major taxiway reconstruction that is currently in the design phase promises to be a hallmark project.

Airport Engineering Assistant Manager Lia Sutanto oversees the design and construction of everything that isn’t vertical—from runways and taxiways to the parking lots. It’s a role she enjoys wholeheartedly.

“PHL is a relatively older airport. It’s landlocked between a river and properties that are difficult to acquire, and built partially on marshlands,” says Sutanto of the constraints. “So, it’s a challenge to grow or expand to meet passenger and shipping demands. Creative thinking is required in everything we do.”

|

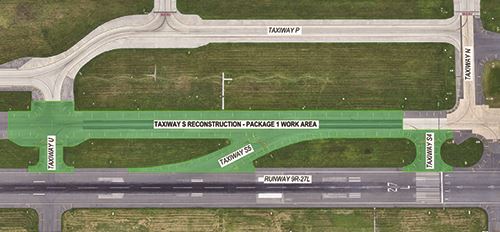

Project: Taxiway Rehabilitation Location: Philadelphia Int’l Airport Taxiway: S Total Length: 16,000 ft. Package 1 Reconstruction Length: 4,000 ft. Width: 75 ft. Pre-Project Pavement Condition Index Rating: 18-39 Estimated Budget: $40 million Design: Jan. 2022–Dec. 2022 Construction Commenced: Feb. 2024 Anticipated Completion: Nov. 2025 Consulting Engineer: Johnson, Mirmiran & Thompson Inc. Sustainability Framework: Envision Envision Administrator: Institute for Sustainable Infrastructure |

As a division of the city of Philadelphia, PHL operates within a broader agenda than some other airports. “Philadelphia has made a huge commitment to sustainability, and PHL plays an important part in that,” Sutanto explains. “Right next to the river, we need pavements that resist high heat. We want to be good neighbors, use fewer resources and achieve zero waste by 2035.”

She sees these objectives as fundamental to “doing good business.” To formalize the process during future infrastructure improvements, PHL and its general aviation sibling, Northeast Philadelphia Airport (PNE), use the Envision certification program.

“Envision is a rating system that fills a gap in building-based rating systems by concentrating on horizontal infrastructure,” explains Sutanto, who has been with PHL for seven years and in civil engineering for nearly 25. All airfield and landside projects at PHL and PNE that cost more than $2 million must be Envision-certified.

The program, now in its third iteration, is managed and administered by the Institute for Sustainable Infrastructure. It was originally developed in collaboration with Harvard University’s Zofnass Program for Sustainable Infrastructure, and the official framework was launched in 2012.

Envision uses 64 sustainability and resilience indicators to award credits that measure a project’s performance in five categories – Quality of Life, Leadership, Resource Allocation, Natural World and Climate and Resilience.

Quality of Life – This category addresses a project’s impact on its host and affected communities, from the health and well-being of individuals to the well-being of society as a whole.

Leadership – Project teams are most successful if they communicate and collaborate early, involve a wide variety of participants, and take a long-term, holistic view of the project.

Resource Allocation – The sustainability of assets and materials needed to build infrastructure and keep it operational are assessed. Key factors are quality, source and characteristics.

Natural World – The system considers how infrastructure projects impact habitats, species and nonliving natural systems that perform critical ecosystem services that clean air and water, produce healthy food, and mitigate hazards to our health.

Climate and Resilience – Envision strives to minimize emissions that contribute to climate change and ensure infrastructure resilience through projects that are informed, resourceful, robust, redundant, flexible, integrated and inclusive.

“PHL is asking project teams to rethink their approach to design and construction within the guidelines of this program,” says Sutanto. “We have several projects pursuing Envision Certification.”

Airfield Example

Sutanto expects the rehabilitation of Taxiway S, a main airfield artery, to be a significant Envision accomplishment.

As the primary airport for the Philadelphia metro area, PHL served 19.6 million passengers last year, with nearly 300 daily departures to more than 120 destinations worldwide. Naturally, that type of traffic volume takes it toll on airfield pavement over time.

The Pavement Condition Index (PCI) for Taxiway S currently ranges from 39 to as low as 18 in some places. Sutanto emphasizes the need for holistic thinking when rehabilitating the important airfield artery.

“This is the singular taxiway feeding our busiest runway,” she notes. “Part of the design evaluation process looks at what we are going to do in the future. Do we need to change anything to meet standards, or can the location be improved? What is the impact of rutting, and will switching from asphalt to concrete improve that? Sort of like rehabilitating an old building, here we’re updating geometry to meet the airport’s near-term needs and long-range goals.”

JMT is the engineering firm leading design services for the crucial project. The design process began in January 2022 and is expected to continue through the end of the year. Plans are to bid the project in early 2023, and construction is slated to begin in spring 2024. Senior Associate Darren D’Achille, PE, is managing the project for JMT. Like his client, he finds a thrill in the day-to-day work.

JMT is the engineering firm leading design services for the crucial project. The design process began in January 2022 and is expected to continue through the end of the year. Plans are to bid the project in early 2023, and construction is slated to begin in spring 2024. Senior Associate Darren D’Achille, PE, is managing the project for JMT. Like his client, he finds a thrill in the day-to-day work.

“An airport is like a small city,” says D’Achille, who has been in civil engineering for 15 years and focused on aviation design and construction throughout his career. “My work touches all aspects of airport engineering from surfaces and safety to electrical and lighting. Intertwining infrastructure with the movement of these massive airplanes in a fast-paced environment makes it very exciting work.”

JMT’s aviation credentials include an on-call contract for civil engineering services with PHL. D’Achille notes that Taxiway S consists of nearly 16,000 linear feet of pavement and currently runs directly parallel to two primary runways at PHL. Approximately 4,000 linear feet of Taxiway S is planned for reconstruction in the first phase of construction. “The plan calls for adjusting the geometry to meet current FAA design standards, along with upgrades to lighting, signage, grading and drainage—basically everything associated with the taxiway and surrounding infield,” he remarks. “Fortunately, the way we have it designed to this point, there appears to be minimal impacts to airport operations while the work is under construction for all of 2024 and a portion of 2025.”

Regarding the impact of Envision on the design, D’Achille describes most of its requirements/criteria as more practical than radical.

The eastern-most portion of the Taxiway S Reconstruction – Package 1 project at PHL.

The western-most portion of the Taxiway S Reconstruction – Package 1 project at PHL.

“Envision helps get a team extremely organized and brings everyone to the table to find ways within the project to cost-effectively reduce resources,” he explains. In addition to the credit-based project evaluation system, the framework also offers personnel credentialing. JMT, for instance, has seven Envision Sustainability Professionals (ENV SPs) on staff throughout the company. PHL has five as well. In general, ENV SPs are considered subject matter experts in sustainable and resilient civil infrastructure.

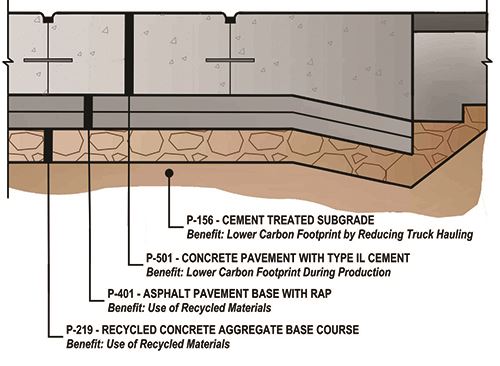

D’Achille cites material sourcing/usage as an example of reducing resources. “Traditionally, in designing a pavement section, we would specify engineered materials brought from off site,” he explains. “Envision is asking us to reuse materials, like recycled asphalt and concrete, taken from on-site sources to create the pavement base layers. These are things we have done in the past, but the certification process brings opportunities like this into focus during team collaborations.”

There are many environmental and economic advantages, and seemingly little downside, with this method, he adds. These are proven methods that meet the requirements of the FAA’s Advisory Circulars for construction specifications. Reusing onsite materials is an exemplar of the program’s objectives. Doing so will not only reduce construction costs, it will also significantly reduce the need to haul materials long distances. Limited material movement can significantly contribute to the reduction of emissions and the project’s embodied carbon count while decreasing area traffic congestion.

Informed Infrastructure

D’Achille notes that one of the key aspects that defines Envision is that it requires applicants to document the project team’s decision-making process for evaluation.

“Leadership is a graded quality,” he comments. “In aviation infrastructure, you need a well-organized process to achieve the planned benefits. Starting a program like this is going to take some time for airport owners and designers to get used to. But once it’s up and running, diligently considering these kinds of strategies should easily become standard operating procedure.”

Sutanto agrees and shares her enthusiasm for the road ahead, as PHL incorporates Envision into the design of Taxiway S and future airfield pavement projects.

“The great majority of the sustainable practices we are considering in this process will save a lot of money for the airport,” she says. “If the concern is the bottom line, the Envision framework isn’t against that. However, like everything else in aviation, it’s a balancing act.”

facts&figures

facts&figures