Be careful what you ask for. It might materialize sooner than expected.

In March 2016, Jeff Huntus, the manager of Medicine Hat Regional (YXH) in Alberta, asked for $12.5 million to replace the airport’s main runway. Transport Canada told him not to expect funds until 2018 or 2019. But in 2017, he received notice that the program had been approved—and for $400,000 more than the airport had requested.

“We were thinking we had another year or two before we had to launch the project,” recalls Huntus. “We went from sitting on our hands, not giving it a lot of thought, to full-bore final design tendering and pushing in place a program whereby we had the runway under construction in one form or another for parts of two years.”

|

Project: Runway Rehabilitation Location: Medicine Hat (AB) Regional Airport Total Cost: $11.5 million Work Scope: Full asphalt replacement; new perimeter sub-drains & catch basins; partial replacement of infield storm sewer system; selective concrete panel repair/replacement at runway turning buttons; new edge lighting components & cabling; new airfield lighting control system Prime Contractor: AECON Transportation West Project Consultant: WSP Global Subsurface Utility Installation: MJB Enterprises Ltd. Manholes, Catch Basins & Headwalls Mfg: Precon Mfg. Lighting, Signage & Control Panel Mfg: ADB Safegate Lighting Installation: Tristar Electric Inc. Runway & Taxiway Markings: Marshall Lines Landscaping & Hyrdoseeding: Grassroots Landscaping Manholes, Catch Basins & Headwalls: Precon Mfg. |

While understandably shaken about the short notice, Huntus was eager to proceed with the project. The airport’s main runway had not been resurfaced since the early 1990s. “It was very much at the end of its useful life,” explains Huntus. “This project would keep us up and running for another 20 years.”

Timely Request

The $12.9 million grant was through the Airport Capital Assistance Program (ACAP) that is administered by Transport Canada, the federal entity that is responsible for transportation policies and programs throughout the country. To date, it is the largest single grant ever awarded under ACAP, which provides funding for improvement projects at regional airports.

Huntus says it was serendipity that YXH’s proposal was submitted at a time when the program was looking for a project that could be completed over two phases and funded in two separate years—2017 and 2018. “We just happened to be on top of the pile,” he jokes.

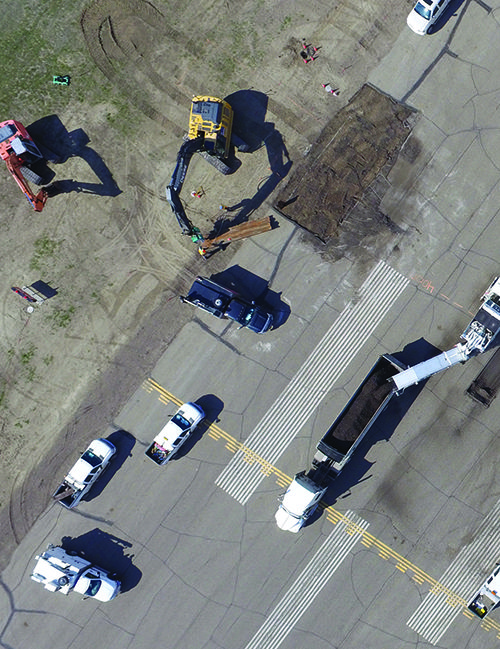

Huntus and a team from the city’s Municipal Works Department scrambled to get the project out for bid. The first phase of the project, scheduled over 10 weeks in 2017, involved replacing the subsurface drainage system and the airfield electrical system. That work was completed exclusively at night to minimize the impact on air traffic. Between 9 p.m. and 5 a.m., the width of the runway was reduced to about 100 ft., temporary lighting was installed and the runway was closed to all operations except emergency medical evacuation aircraft.

During the project, the airport averaged about two medevac flights per night. The airplanes were usually flying patients from the local regional hospital to a larger hospital in Calgary, explains Huntus. Each time a medevac airplane had to land, the work crews pulled their equipment off the runway and covered any trenches that were open along the edge of the runway. “It caused us a little bit of grief, but we factored that into the timing,” he says.

A Difficult Decision

When the runway project was announced, YXH had commercial service from Air Canada. Immediately after the project was completed, WestJet Airlines also began service. The airport tallied 36,000 passengers in 2017. Huntus estimates that 70% of the traffic is business and 30% is leisure. The area has a vibrant agriculture industry and active oil/gas sector, which brings in corporate jets as large as the long-range Gulfstream V.

To facilitate the project’s second phase—the removal and replacement of the main runway—the airport closed to air traffic completely for 24 days last May. Alternative plans were considered, but in the end, shutting down completely was deemed the best way to cause the least amount of disruption for the shortest amount of time.

Before opting for the full closure, the airport considered one other strategy. Because YXH has two intersecting runways, project designers contemplated renovating the main runway in two sections to allow the shorter runway to remain open during construction. That plan was vetoed because the secondary runway is 2,800 feet, which is too short for the Air Canada flights and the air ambulance contractor. If the short runway was kept open for other aircraft, construction would have been limited to nighttime hours, which would have ballooned the project duration from 24 to 49 days.

“Going with the full closure was the most difficult decision I’ve ever had to make,” Huntus reflects. “It impacted charter operators, the medevac operators that had to relocate to another airport, flight training schools, the FBOs—they all suffered.” The project also affected the airport’s rental car operator, restaurants and other terminal services that remained open during the closure.

“It was definitely not a decision that we made lightly,” agrees Carlie Collier, a municipal engineer who served as the project manager. “It was over a long process where we had discussions with our consultants, looked at our options, had discussions with the air carriers and really tried to look at the best way to get the project done with minimal impact to the users.”

“It was definitely not a decision that we made lightly,” agrees Carlie Collier, a municipal engineer who served as the project manager. “It was over a long process where we had discussions with our consultants, looked at our options, had discussions with the air carriers and really tried to look at the best way to get the project done with minimal impact to the users.”

When airport officials announced the plan to close to air traffic for more than three weeks, they received a lot of pushback from operators and negative coverage in the local press. “Reporters being reporters, they found every possible angle to support how bad that news was,” Huntus says. The president of one charter and flight training company operating told the press that his company was considering legal action against the city, but no suit was filed.

One week after news of the closure hit, the airport enjoyed somewhat of a public relations rebound, when it announced that WestJet would introduce commercial service at YXH as soon as the new runway opened. It was good fortune to have positive news to share, recalls Huntus.

While he was prepared to face the fury of local entrepreneurs, his main concern was displacing air ambulance service for 24 days. Alberta Health Services contracts with private aviation companies to fly King Air 250s throughout Alberta for critical transfers.

“That was the thing that kept me awake,” recalls Huntus. “You’ve got code red patients who are regularly transported from here to the major health services in Calgary. In the back of your mind you’re thinking, ‘What happens if they’re needed and can’t fly out of here?’” A contingency plan put in place by Alberta Health Services, the provincial health agency, called for urgent transfers to be serviced out of Bow Island Airport. Much to Huntus’ delight, none were needed during the 24 days of construction.

Race to the Finish

The planning team chose May 7 to 31 to complete the critical second phase of the project, because it is historically one of the driest months of the year. Personnel from AECON Transportation West, the project’s general contractor, felt that the 24-day window was tight but achievable—if the weather cooperated.

“The scope of work, as far as asphalt removal, laying down a granular base and then paving…we do that every day. The only unknown was the weather, and that made everybody nervous,” relates Jon Wilson, AECON’s operations manager. “The 24 days was written into the contract when we bid on it, and we had contingency plans set up in case we fell behind so we could work around the clock.”

“The scope of work, as far as asphalt removal, laying down a granular base and then paving…we do that every day. The only unknown was the weather, and that made everybody nervous,” relates Jon Wilson, AECON’s operations manager. “The 24 days was written into the contract when we bid on it, and we had contingency plans set up in case we fell behind so we could work around the clock.”

As it does with many of the large highway projects it tackles, AECON mobilized and set up an asphalt plant on site at the airport to minimize time for hauling and increase production on site.

Moreover, Mother Nature cooperated. There were only two rainy days during the construction period, and one was the last day, when the work was done and crews were just cleaning up.

Collier and Wilson both credit the extensive planning done by the project team as the key to finishing on time and under budget. The project was completed for $11.5 million—more than $1 million less than the original grant request. As required, the extra funds were returned to ACAP.

“The preliminary work was key,” Collier comments. “There was a lot of preparation leading up to the work in May, and everyone was aware of what needed to get done. It came down to good project management from our consultants and contractors. And we definitely lucked out with the weather.”

Wilson notes that extensive planning also helped keep the construction site safe throughout the 24-day closure.

What the Project Entailed

|

facts&figures

facts&figures