Airports, along with other public agencies, are essential to a community’s economy and quality of life. Greater Moncton Roméo LeBlanc International Airport (YQM) in Dieppe, New Brunswick, codified this sentiment by partnering with another critical public utility.

Airports, along with other public agencies, are essential to a community’s economy and quality of life. Often, airport executives and other airport personnel take great pride in the significant role their facilities play in the day-to-day functioning of the communities they serve.

Greater Moncton Roméo LeBlanc International Airport (YQM) in Dieppe, New Brunswick, codified this sentiment by partnering with another critical public utility—the area’s wastewater treatment commission—and the city of Dieppe to resolve the challenge of safely discharging runoff from the airport’s glycol deicing operations.

In 2018, TransAqua, the wastewater treatment facility for Greater Moncton, put YQM officials on notice that it would likely not be able to accept the airport’s glycol-infused runoff once the company’s new $90 million biosolids water-treatment facility was completed in 2020. The wastewater treatment facility was upgrading its secondary treatment systems to meet federal effluent regulations, and management wanted to make sure that airport discharges containing spent deicing fluid did not negatively impact the new system.

|

facts&figures Project: Glycol Management Upgrade Location: Greater Moncton Roméo LeBlanc Int’l Airport Total Cost: $7.5 million Funding: 50% via Federal government’s National Trade Corridors Fund Construction: June-Nov. 2020 General Contractor: Dexter Construction Glycol Collection Center Design & Construction: Nexgen Municipal Inc. Accolade: Environmental Improvement with Limited Resources Award from Airports Council International – North America |

Pondering Solutions

Gemma Askeland, environmental and regulatory specialist for the airport, notes that YQM considered several options, including building its own onsite wastewater treatment plant or trucking runoff to a wastewater treatment facility in Halifax, a 2½-hour drive from the airport. Unfortunately, neither of these nor other ideas was desirable due to operational and environmental issues.

Meanwhile, Doug Vanderlinden, president of Nexgen Municipal Inc., reached out to airport leadership after reading a news report about YQM’s dilemma. His company had developed and constructed a new airport wastewater solution for Frederick Douglass Greater Rochester International Airport in New York and Westchester County Airport in White Plains, NY.

Within the last decade, the company has pivoted from building large membrane-based treatment systems on airport land to focusing on partnering and using existing infrastructure from publicly owned treatment works. Vanderlinden thought the concept might benefit YQM.

After Nexgen personnel explained the approach to airport management, they focused on educating officials from TransAqua and the city about the company’s affordable solution to prevent YQM from discharging stormwater with levels of glycol that exceed environmental limits. Key decision-makers from the airport, city and wastewater treatment facility toured Westchester County Airport and were assured by their counterparts there that Nexgen’s concept was 100% effective.

“We built a partnership between ourselves, the airport and TransAqua,” Vanderlinden remarks. It is particularly important to involve the publicly owned treatment works (in this case, TransAqua) in the initial planning and design, he adds.

“We built a partnership between ourselves, the airport and TransAqua,” Vanderlinden remarks. It is particularly important to involve the publicly owned treatment works (in this case, TransAqua) in the initial planning and design, he adds.

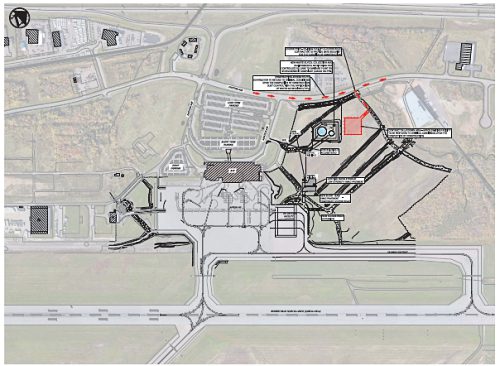

The $7.5 million project, completed in November 2020, required some construction on airport land. New underground infrastructure was installed, two new buildings to house control systems were built, and two aboveground storage tanks were built next to the terminal building. Construction began in June 2020, and the system came online in November the same year. It was 50% funded through the federal government’s National Trade Corridors Fund.

On-Site Analysis In Real Time

Before the new glycol management system was added, YQM simply released its glycol effluent into the city system and associated wastewater treatment plant through an underground tank. Glycol levels were not monitored.

When TransAqua notified the airport that it would, in fact, not be able to discharge glycol-infused runoff through the treatment plant’s upgraded water-treatment system, YQM officials knew they had to resolve the issue. Instead of building elaborate onsite storage and treatment facilities, the airport embraced Nexgen’s approach and spent significantly less capital and operating expenses by using existing city infrastructure.

“This is really a story about capital conservation at the airport by utilizing locally available municipal infrastructure,” Vanderlinden explains. “It’s an excellent demonstration of a partnership with the airport and host community. Over the years, some airport glycol discharges have challenged local sanitary sewers because [there was not a clear understanding about] the extreme load spent de-icing fluid exerts on them. When we bring these parties together and share loading calculations, control methods and oversight as well as participate in the planning, design and operation of the process, the results have been very good.”

The field trip to see the system at Westchester County Airport and speak with wastewater treatment facility officials proved to be reassuring. “When we visited, we saw that they were able to communicate closely with the airport and did not report any issues,” relates TransAqua General Manager Kevin Rice. “This helped us have confidence in the new system and the ability of the biological process to handle the glycol with no adverse effects.”

The field trip to see the system at Westchester County Airport and speak with wastewater treatment facility officials proved to be reassuring. “When we visited, we saw that they were able to communicate closely with the airport and did not report any issues,” relates TransAqua General Manager Kevin Rice. “This helped us have confidence in the new system and the ability of the biological process to handle the glycol with no adverse effects.”

Initially, the airport intended to make other improvements while building and installing the new deicing facility equipment. Plans included expanding the main apron, expanding the deicing pad and improving the access road just off the deicing pad. However, the expansion plans were shelved when COVID hit, and airport officials became concerned about lost revenue from severely diminished passenger and cargo volume.

Nexgen Municipal provided concept design services for the surviving project, laid out the electrical and mechanical systems, and calculated the publicly owned treatment works loading and ramp hydraulic loading. The airport was responsible for completing the civil work, which included building the pump houses and the storage tanks.

Here’s how the new automated system works:

Stormwater runoff from the deicing pad is captured in underground infrastructure, and then sent to the Nexgen glycol management system, where it is analyzed for glycol content in real time. If the glycol concentration is below environmental guidelines, the runoff is released to the airport stormwater system. If the concentration is above guidelines, the runoff is captured and sent to one of two aboveground storage tanks—a 750,000-gallon tank for low-concentration stormwater, and a 250,000-gallon tank for high-concentration runoff. Once captured in the tanks, runoff is released by a second Nexgen system at a controlled rate to TransAqua via the city’s sanitary sewer system. Alternately, the system can pump runoff to a tanker truck. The system automatically ramps up and down to further protect the sanitary system.

Much of the system operates automatically. In her capacity as YQM’s environmental specialist, Askeland joined the mechanical maintenance group for a couple days of training about the new monitoring equipment. Nexgen provides ongoing system support and also monitors system performance and glycol levels remotely.

TransAqua can also monitor the airport’s glycol management system in real time just as YQM itself does. If TransAqua sees glycol levels that exceed its load capacity, personnel can alert the airport and override the runoff delivery system. In the nearly two years the system has been operating, this has never been needed. The ability to do so, however, provides the confidence that wastewater treatment plants need to commit to the system, notes Vanderlinden.

“A lot of publicly owned treatment works just didn’t want to take airports’ discharge,” he elaborates. “We changed that conversation by implementing very strict measurement, sensing and control strategies. We give airports the confidence that anything that comes off their deicing pad that’s noncompliant is going to be captured, and we give sanitary sewers the confidence that airport discharges to their treatment facilities will not exceed agreed permit levels.”

The new system at YQM is attracting attention throughout the industry. Last year, Airports Council International – North America (ACI-NA) recognized the New Brunswick facility with an Environmental Achievement Award for environmental improvement with limited resources.

Askeland notes that the glycol management project is the latest in a lengthy list of projects the airport has completed to be an environmentally conscious member of its local community. In 2015, YQM became an early North American participant in ACI’s global carbon footprint reduction initiative. In 2019, it was one of only five Canadian airports to reach the third of four tiers in the accreditation program, which ultimately aims to achieve carbon neutrality.